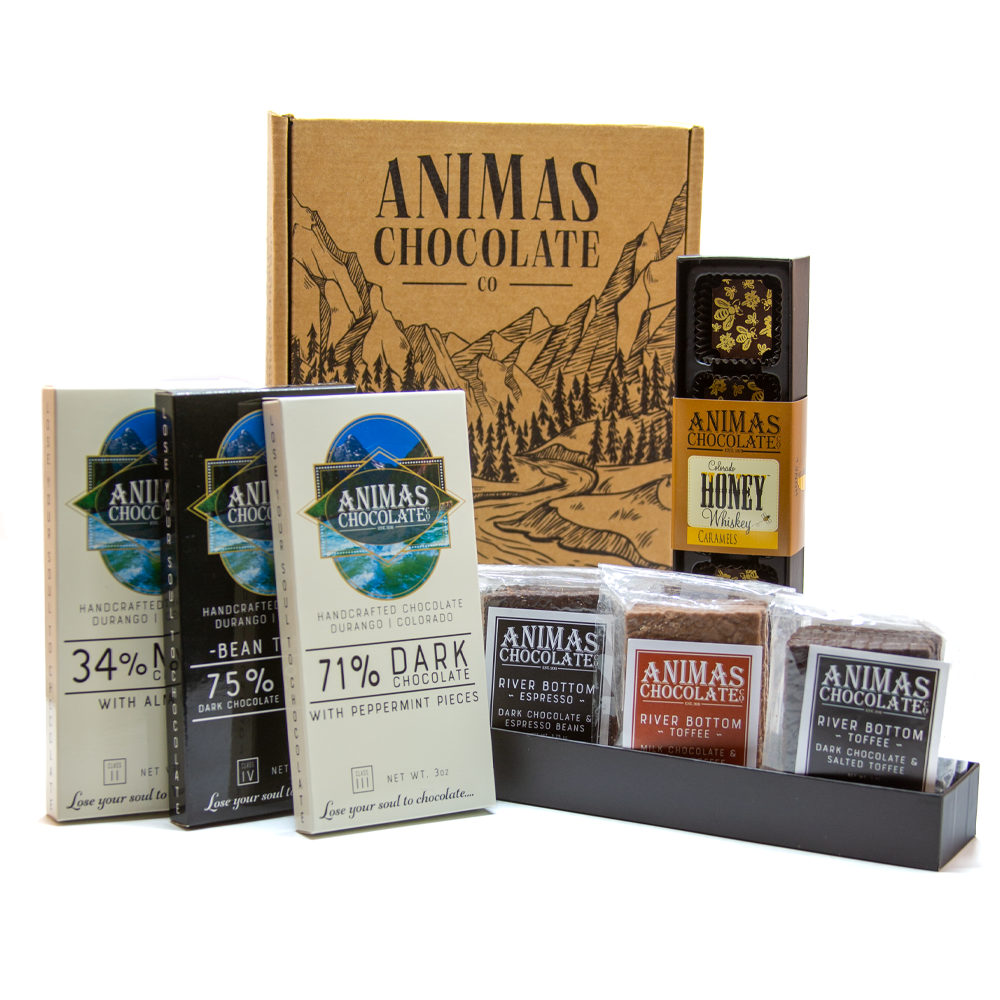

Bean to Bar

We are proud to be one of a handful of shops in the world who are both craft chocolatiers and artisanal Bean-to-Bar chocolate makers. If you want clarification on what this means, see our ABOUT page.

So what is Bean to Bar? It simply means that we source Cacao in it’s native form (it’s a fruit!) and process this fruit into what we call chocolate. From there, our chocolatiers further refine and take that chocolate and make it into chocolate confections like bars, truffles, etc.

In the case of the chocolate we make, we source cacao from unique single origin locations that produce the highest quality cacao. These regions, such as: Belize, Haiti, Guatemala, and Uganda have small farms that have incredibly unique flavor profiles and tasting notes . The beans come to us in large burlap bags which we then transfer to a sorting table to remove any unwanted beans or debris. We are incredibly lucky to roast our single-origin cacao at Durango’s own Desert Sun Coffee Roasters, a local fair trade and certified organic roastery, and partner of our cafe. From there, the roasted cacao goes through four unique steps: cracking, winnowing, melanging, and conching. Each of these steps is done with the utmost attention to detail by our staff and results in our Highline bean-to-bar collection – chocolate bars that will fundamentally change your perception of what chocolate can taste like.

Each step in the process of creating bean-to-bar chocolate is essential. Read on to learn more about each step we take to craft our incredible Highline bean-to-bar chocolates.

Roasting – our raw cacao is roasted in a 30kg Diedrich Roaster. We roast cacao at Desert Sun because their large roasters allow us to roast with extreme consistency, and we develop a unique roast profile for each origin. This is the first choice a chocolate maker actively makes in the process that will drastically impact the final flavor of the chocolate.

Cracking – The roasted cacao bean has a hard shell that is cracked and opened so that the nib inside can be accessed.

Winnowing – Both the hard shell and the “husk” (or thin myelin layer that surrounds the nib) must be removed before we can begin to grind the nibs. We go through several rounds of winnowing , and then a final pass of sorting by hand- to ensure quality.

Grinding – Our melangeurs allow us to grind the the cacao nibs into a paste called chocolate liquor. It should be noted that chocolate liquor is not alcoholic, but is so named because as the nibs are ground, the natural cocoa butter liquifies and the once solid cocoa mass becomes a liquid. This liquor (again, NOT alcoholic) contains cocoa solids and cocoa butter in roughly equal proportion. It is at this stage that we add organic cane sugar to create chocolate. We grind our chocolate for 48 hours – this affects the size of the particles in the chocolate to create a smooth feel in the mouth.

Conching – We conche our chocolate for 24 hours. Conching further refines the chocolate liquor by aerating the chocolate and releasing unwanted astringency.

At this point the chocolate liquor is poured from the melangeur into large moulds, sealed and moved into our production kitchen where our chocolatiers will soon temper and form the chocolate into bars, truffles and other chocolate confections.

We invite you to try each of our Highline bean-to-bar varieties to discover the unique flavor profile of each one. Our small-batch bean-to-bar chocolate are made at 75%, meaning that the bar is 75% single origin cacao and 25% organic cane sugar – and nothing else. We feel this recipe brings out the most flavor of the bean, while still maintaining a level of sweetness that is completely enjoyable.

Plus, we welcome you to have a look at our Bean-to-Bar room the next time you’re in our cafe. Any of our staff would be more than happy to talk with you about the process and their role in it. It’s a labor of love, and the results are superlative.